keys are accurately set without the costly investment of purchasing a

press with a CIP3 or CIP4 ink reader.

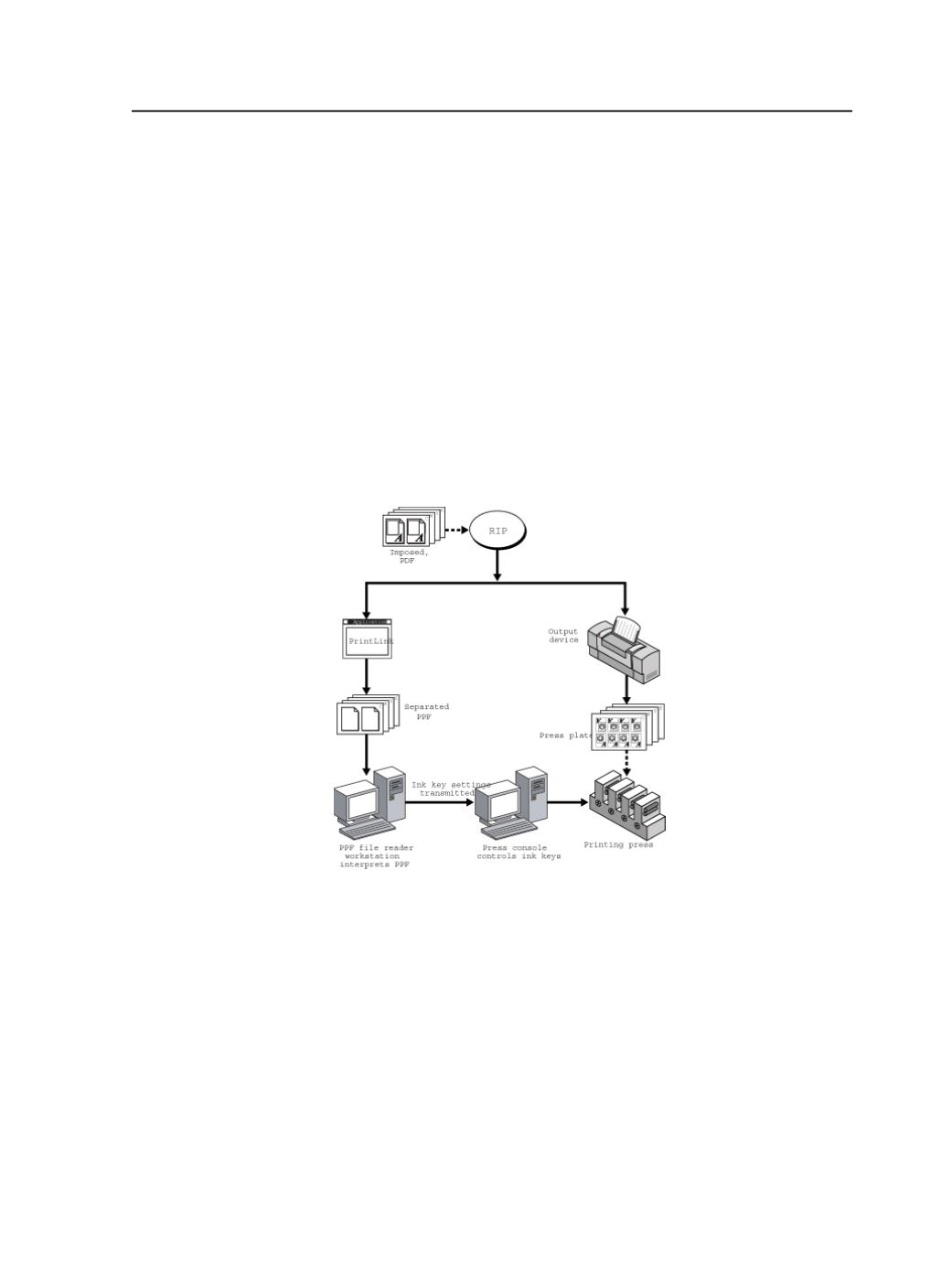

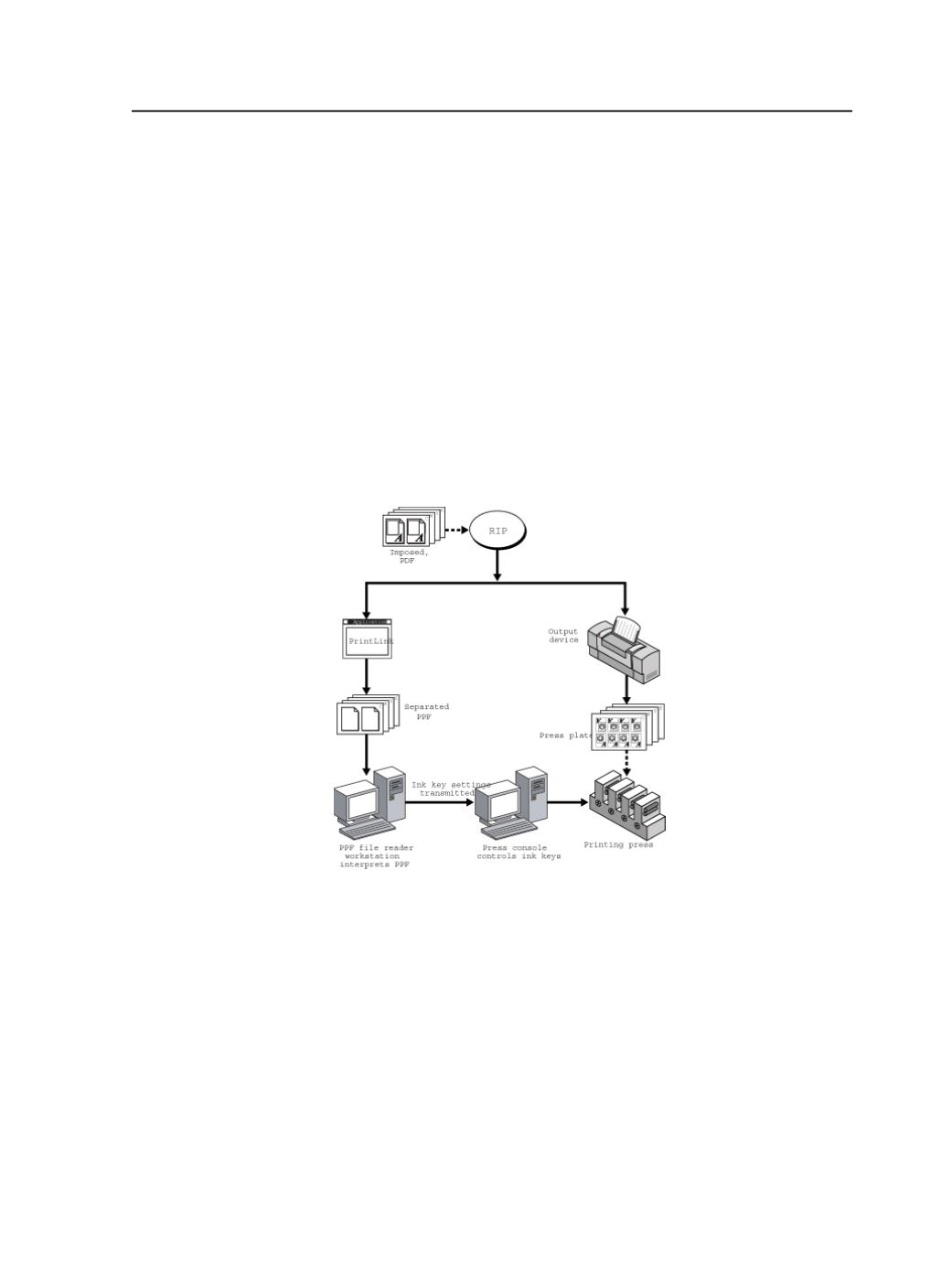

How PrintLink works in a Prinergy workflow

1. Your imposed PDF files are sent to the RIP on a secondary server.

2. The RIP on the secondary server receives the imposed files, RIPs the

data, and delivers the high-resolution raster to your output device.

3. While the RIP delivers the raster for plate imaging, PrintLink

generates a PPF file, one file per separation.

4. The resulting separated PPF file is sent to the PPF file reader

workstation.

5. The PPF file reader workstation interprets the ink coverage data.

6. The digital ink key settings are transmitted to the press console,

which controls the ink keys based on the PPF information it

receives.

Ink reports

You can generate an ink report from the PPF files produced by

PrintLink. The ink report is a text-based report that describes the area

of ink coverage (in square centimeters and inches) and the percentage

of the plate covered.

Custom PPF file

PrintLink produces PPF files that comply with the International

Cooperation for Integration of Prepress, Press, and Postpress (CIP3)

PPF file specification. CIP3 has established an open standard for

exchanging information among print production devices from multiple

vendors, including platesetters, presses, and finishing equipment.

PrintLink

743