About common density limit

Common Density Limit

is used to prevent traps where they are not

needed. Traps are not needed if a gap will not be visible due to the

darkness or density at that place. It is controlled from the

Trap

section

of refine process templates.

Common density is a neutral density calculated from the common

parts of each single separation. In the table below, C60 M25 Y30 K10

and C40 M31 Y40 K14 have the common parts of C40 M25 Y30 K10.

Spot colors are also considered, if present. Therefore, the common

density is a value for the darkness for the worst possible

misregistration. If this common density is above the

Common Density

Limit

setting, no traps are required.

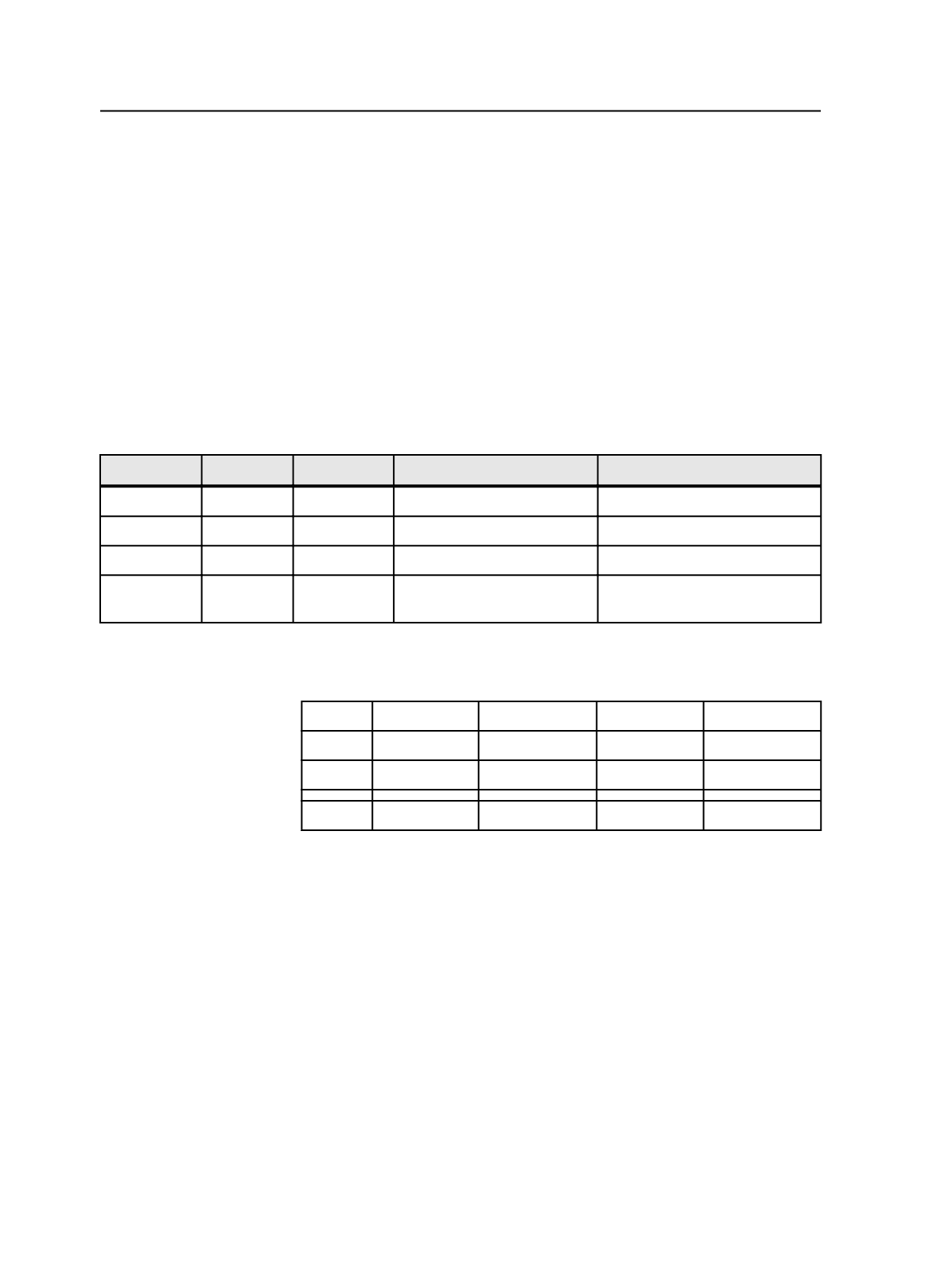

Separation Color1

Color2

Relative Ink Dot Percentage Step Limit (25%) Satisfied?

Cyan

60% 40%

(60-40)/40 = 0.5 or 50% Yes, 50% >25%

Magenta

25% 31%

(31-25)/25 = 0.24 or 24% No, 24% < 25%

Yellow

30% 40%

(40-30)/30 = 0.33 or 33% Yes, 33% > 25%

Key

10% 14%

Ignored, doesn't meet 5%

minimum difference

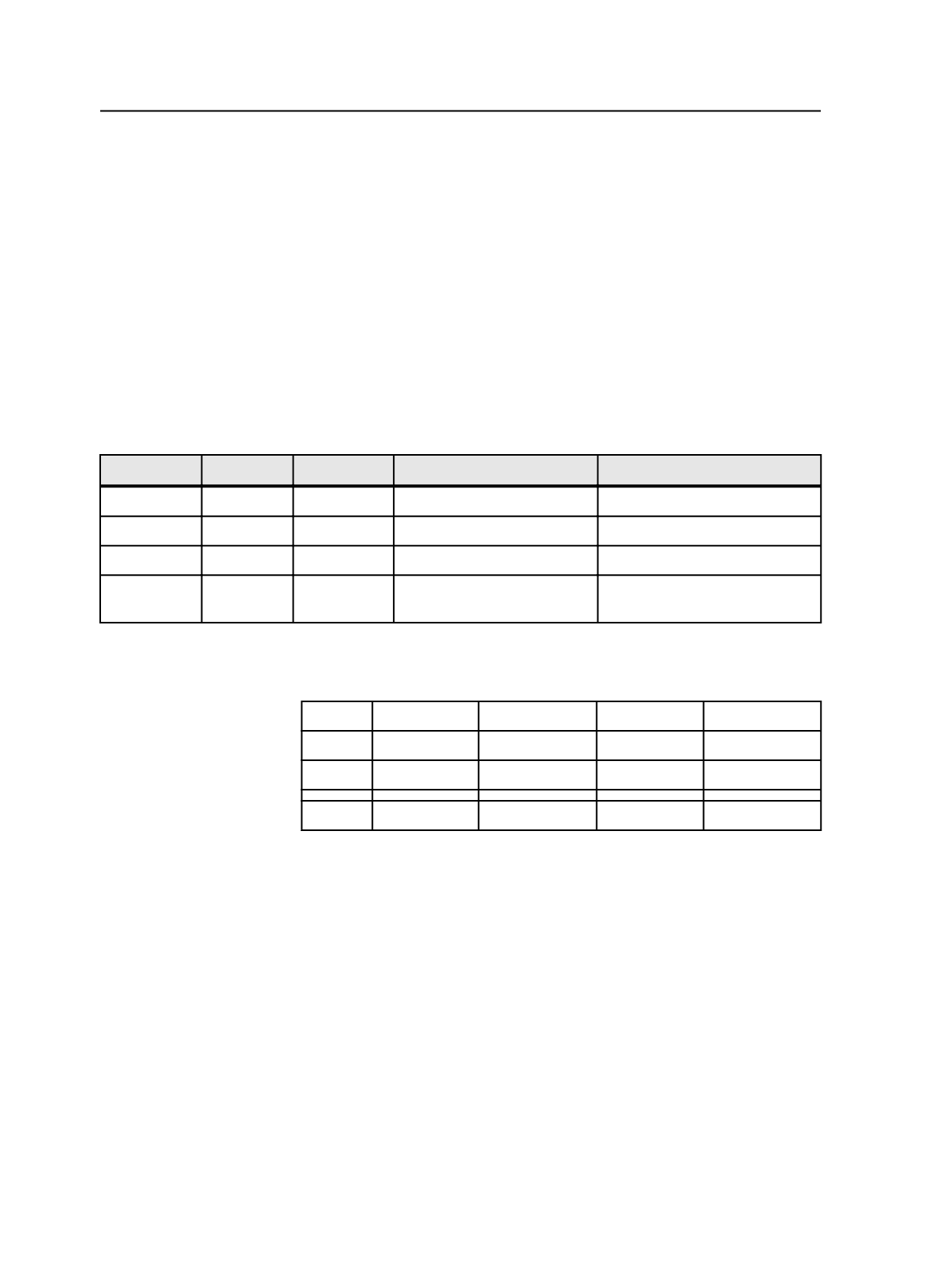

For the example above (common parts of C40 M25 Y30 K10), the

common density is calculated as follows (CD = common density, ND =

neutral density):

CD = ND[Cyan] + ND[Magenta] +ND[Yellow] +ND[Key]

= 0.19

+0.13

+0.05

+0.07

= 0.44

0.44 < 0.5

The common density of the two example colors is lower than the

default limit of 0.5, so a trap would be created.

About neutral density

You can control neutral density from the

Trap

section of refine process

templates.

All inks used for printing do not have the same darkness. For example,

yellow is lighter than cyan. Neutral density is used to specify the

darkness of a printing ink on paper. A neutral density of 0 is white (no

ink). For process colors, the neutral densities vary, depending on the

ink set (for example, EuroOffset, SWOP. For spot colors, neutral

density can be explicitly specified. If a spot color is normal (non-

opaque), neutral density can also be estimated from a given color.

256

Chapter 10—Refining